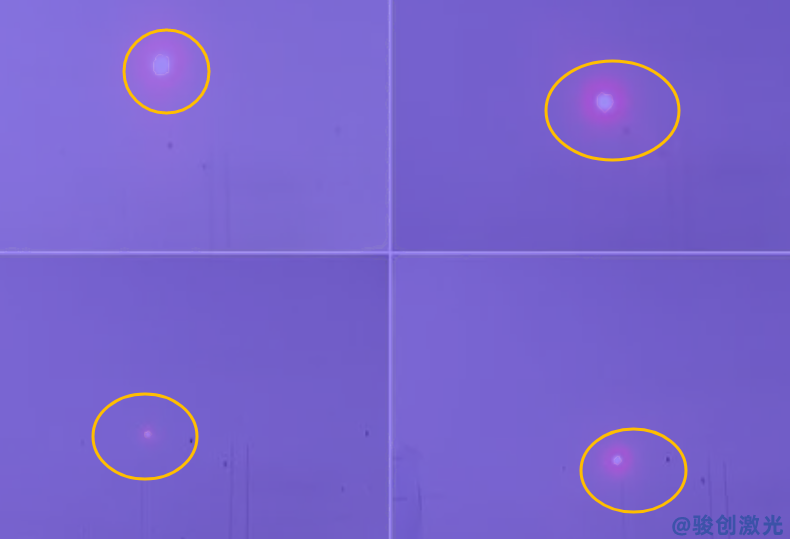

Laser marking machines are widely used in industrial labeling, engraving, and marking, with spot size being an important factor affecting marking quality and results. However, many people believe that the spot size of laser marking machines is adjustable, but this view is not entirely accurate. This article explores the characteristics of laser marking machine spot size and its adjustment limitations. Principle of Spot FormationThe laser spot in a laser marking machine is formed when the laser beam is focused through the optical system. The spot size is primarily determined by the laser wavelength, the design of the optical system (including lenses and mirrors), and the laser focusing conditions. Once these factors are fixed, the characteristics of the spot are essentially determined. Limitations of Spot Size AdjustmentWhile it is possible to change the spot size by adjusting the focal length or using different lenses in certain cases, such adjustments are not flexible and have limitations: Fixed Optical System: The optical systems in most laser marking machines are designed for specific applications, and the spot size cannot be arbitrarily adjusted. Focal Length Limitation: Changing the focal length may affect the distribution of laser energy, leading to uneven marking results. Material Adaptability: Different materials require different spot sizes, and excessive adjustments may result in unsatisfactory marking effects. Design ConsiderationsLaser marking machines are typically designed to achieve optimal marking results under specific conditions. Manufacturers optimize the optical systems based on market demands and application scenarios to meet specific marking requirements. Therefore, changing the spot size often impacts other parameters, such as marking speed, power, and material compatibility. Relationship Between Marking Quality and Spot SizeWhile the spot size is an important factor influencing marking quality, it is not the only factor. Parameters such as laser power, speed, and frequency are also critical. In actual applications, these factors should be considered together to achieve the ideal marking results. In conclusion, the spot size of a laser marking machine is not a parameter that can be freely adjusted; it is determined by the optical system and design characteristics. Understanding the characteristics and limitations of the spot can help users better optimize marking results and improve production efficiency. For different application needs, selecting the right equipment and parameter settings is key to achieving the best marking effects.

Knowledge of laser marking machine

Common Misunderstandings in Adjusting the Spot Size of Laser Marking Machines

2025-01-13 Visits: